Some woodworking tools, like saws and sanders, are found in virtually every woodworking shop. Other, like wood jointers, are less common. No other tool does the task a jointer does, but not everyone needs it — at least not to the degree of precision a jointer makes possible.

Store-bought lumber already has flat faces and edges, and for a beginning woodworker they’re flat enough for most purposes. Cabinetmakers constructing high-quality dressers and tabletops, however, need smoother, flatter, straighter edges than those on factory-milled wood, and for them, a jointer is essential. It’s also a handy tool for anyone who works with rough or reclaimed lumber.

What Is a Wood Jointer?

A wood jointer is a benchtop or stationary planing tool. It consists of in-feed and out-feed tables (which together form the “bed”), a fence and a cutting head.

You set wood with one face or edge flat on the in-feed table, holding it tightly against the fence and pushing it through the blade, which then shaves off a layer of wood. A jointer mills one face and one edge of a piece of lumber perfectly flat and smooth and squares the corner between them.

The width of the in-feed and out-feed beds determine the maximum width of wood the jointer can handle. Bed width varies, but six inches is the most common.

The bed length determines how long a board you can comfortably surface without setting up in-feed and out-feed tables. The average is around three feet, but they can be as short as 28 inches or as long as 72 inches. Generally, the maximum length of wood you should use on a jointer without in-feed and out-feed support is twice the length of the bed.

What Is a Wood Jointer Used For?

Because the action of a jointer is similar to a planer, it’s easy to confuse the two. But a jointer is a specialized tool with a specific purpose: milling one face and making one perpendicular flat edge suitable for clean butt joints. That’s why it’s called a jointer. Woodworkers commonly use jointers to flatten out warps and irregularities.

If a board is cupped (meaning the edges are raised), you can flatten it by feeding it repeatedly through a jointer to shave down the edges. The reverse side of the board will still be crowning (the opposite of cupping), however, and pros caution against trying to correct both sides with a jointer. Because you’re pushing down on the top, you have no way of correcting a board that’s already tapered.

How Does a Wood Jointer Work?

The heart of a wood jointer is the spinning cutter head. Many of today’s jointers feature spiral or helical blades for better efficiency.

The top edge of the cutter is exactly flush with the out-feed table, which is stationary, and the in-feed table can be precisely adjusted slightly lower than the out-feed table. The blade shaves an amount equal to the height difference of the tables.

The fence is as important to successful jointing as the bed and the blade. It must be sturdy and precisely engineered to a 90-degree angle to the bed. If you flatten an edge of a board, then hold the board firmly against the fence as you pass the face through the blade, you’ll end up with a perfectly square edge.

Wood Jointer vs. Planer

Woodworkers who mill their own lumber, reclaim it from demolition projects or purchase rough sawn lumber to save money need a tool that can turn a mottled, wavy surface into a flat one. A jointer can do that, but so can a planer. And in many circumstances, the planer does a better job. But if making tight, seamless joints is your primary concern, a wood jointer is the tool for you.

A planer uses the same type of horizontal spinning cutter. The difference: A planer’s cutter is positioned over the wood rather than underneath. On a planer, the wood rests on an adjustable table; unlike a jointer, a drive gear feeds the wood through the machine. You regulate the thickness of the board by raising the table (usually by no more than 1/8-in. per pass) and the surface quality by adjusting the speed of the drive.

Because of its flat table and automatic drive, you can use a planer to surface all four sides of a piece of wood to achieve the exact dimensions you want. You can’t do this with a jointer because you’re manually pushing the wood into the cutter. If it’s tapered or uneven, it will stay that way.

But the jointer is still handy because it allows you to flatten and square one side and one edge before feeding wood through the planer. You don’t necessarily have to choose one or the other, because combination planer/jointers are available. Benchtop models often cost less than if you were to purchase a planer and jointer separately.

What Size Wood Jointer Do I Need?

Most woodworkers only need a standard bed six inches wide and 28 to 36 inches long. You can opt for an eight-, 10- or 12-inch bed if you regularly flatten wide stock. If you regularly work with long boards, you may benefit from a bed that’s 48 or 72 inches long. But a standard bed works well for most purposes.

Best Wood Jointers

If you’re looking for a jointer, you have three options — benchtop, freestanding and jointer/planer combo. Here are our picks for the best of each:

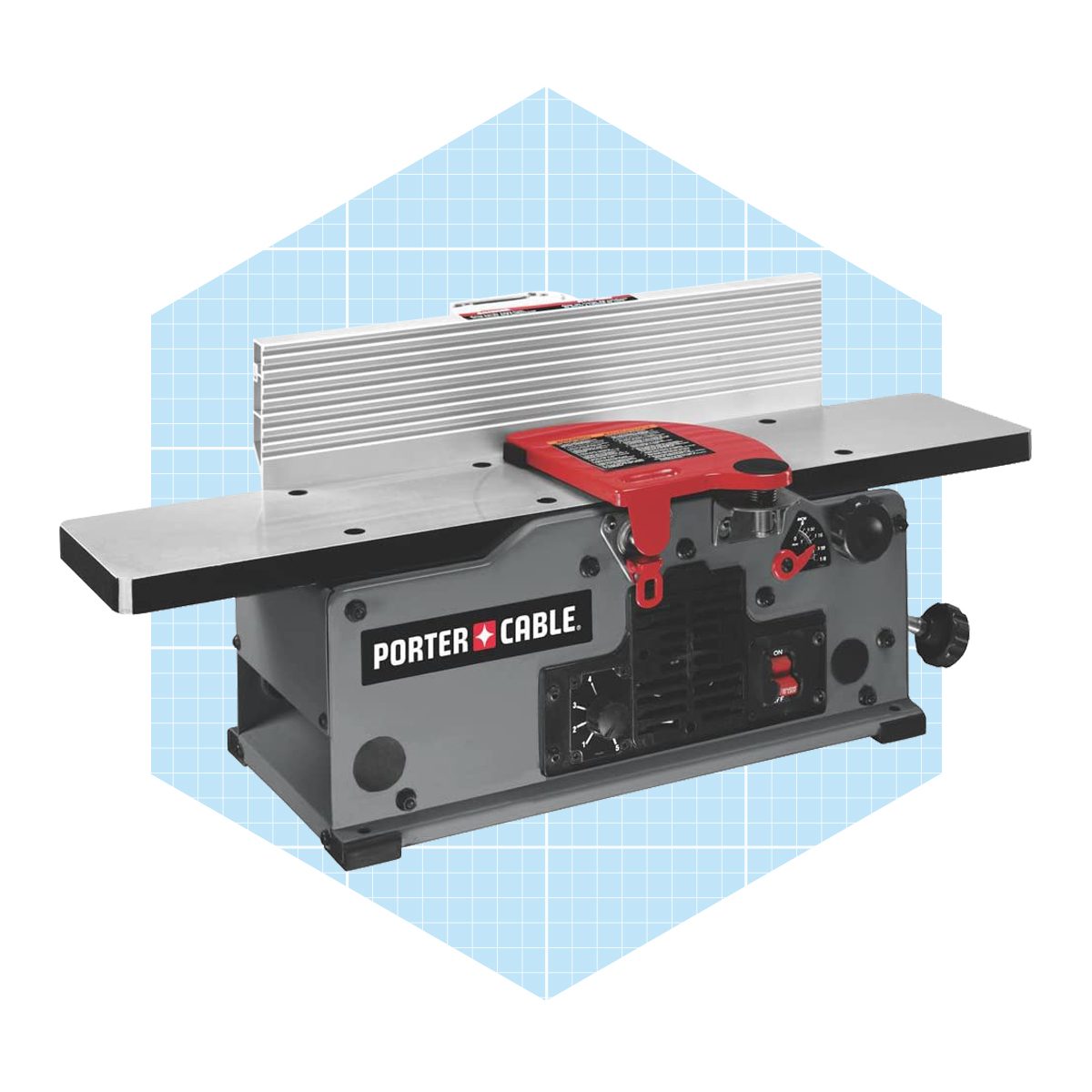

Best benchtop jointer

The Porter-Cable Benchtop Jointer comes with a six- by 31-inch bed and a sturdy sheet metal base. The tool weighs 35 pounds, enough to keep it stationary on the bench but not enough to make it difficult to move. Variable speed control allows you to set the cutter to the type of wood you’re milling.

Best freestanding jointer

If you’re serious about jointing, the Powermatic Eight-Inch Jointer will be a valuable addition to your shop. This product can accept a conventional three-knife or helical cutter head powered by a two-horsepower, 240-volt motor. It features an extended bed (73 inches) for jointing long boards. It’s expensive, but one of the best-reviewed jointers online.

Best jointer/planer combo

If you’re going to pay extra for a machine that combines jointing with planing, you might as well get one that can handle all kinds of stock.

With its 12-inch width capability and three horsepower, 240-volt motor, the Rikon 25-210H is such a machine. It’s rugged and accurate, but reviewers found it easy to set up. There’s also an optional mobility kit so you can easily move this tool around the shop.