If you’re like most people, your first exposure to staples was probably binding together the pages of a homework project. Paper staples are, ahem, a staple in every school and office in the world.

Lots of products apply staples, from mini-staplers to heavy-duty implements that can bind 130 sheets of paper at once.

Staples aren’t just for paper, though. Woodworkers, electricians, builders, flooring installers and upholsterers all use them, and they aren’t the staples you remember from high school. They’re longer, beefier and in many instances do the same job as nails. And they all work in essentially the same way.

In most cases a triggering mechanism releases a spring-loaded hammer that pushes the staple from an aperture with enough force to sink it into the intended material. Staples fence builders and electricians use are exceptions; they hammer those in.

If you do work around the house, you’ll need staples at some point, so it’s good to know what kinds are available and how to use them.

Consideration When Buying Staples

Staples are simple metal fasteners that differ in small but significant ways. Each has a roughly U-shape. The head of the staple (called the crown) is usually square, although it can also be round or triangular. The two sections extending vertically from the crown are the legs, with the tip of each leg called the point.

Here are the main ways staples vary:

- Crown: Crown width ranges from narrow (1/4-inch) to wide (one inch or more). Narrow and medium widths are best for woodworking and upholstery, while wide ones are most appropriate for packages and cartons.

- Legs: Leg length varies from several millimeters to an inch and a half or more. When choosing leg length, multiply the thickness of the material you’re binding times three. When fastening thin materials, it’s customary to add 4-mm to the thickness of the material. When fastening hard materials like wood, double the thickness.

- Wire gauge: This measures the thickness of the staple It varies from 22 (thin) to 10 (heavy). Use thin gauge staples (20-22) for upholstery, vinyl and paper; medium gauge (18-19) for woodwork, house sheathing, subflooring and similar purposes; and heavy gauge (10-16) for furniture framework, roofing shingles and other construction purposes.

- Material: Galvanized steel is the most common. You can also buy copper-coated staples, often used for packaging. Aluminum staples for woodworking projects are easier on saw blades. Stainless steel staples work best when you need better corrosion resistance.

Stapling Tools Pros and Cons

There is usually a selection of tools for particular classes of staples. The variety of paper staplers available provides a familiar example. You can choose a standard desktop stapler, a handheld one, one with an elongated base for stapling booklets or a compact mini-stapler to save space in your drawer.

Here’s a rundown of the more heavy-duty tools you might need, depending on the project:

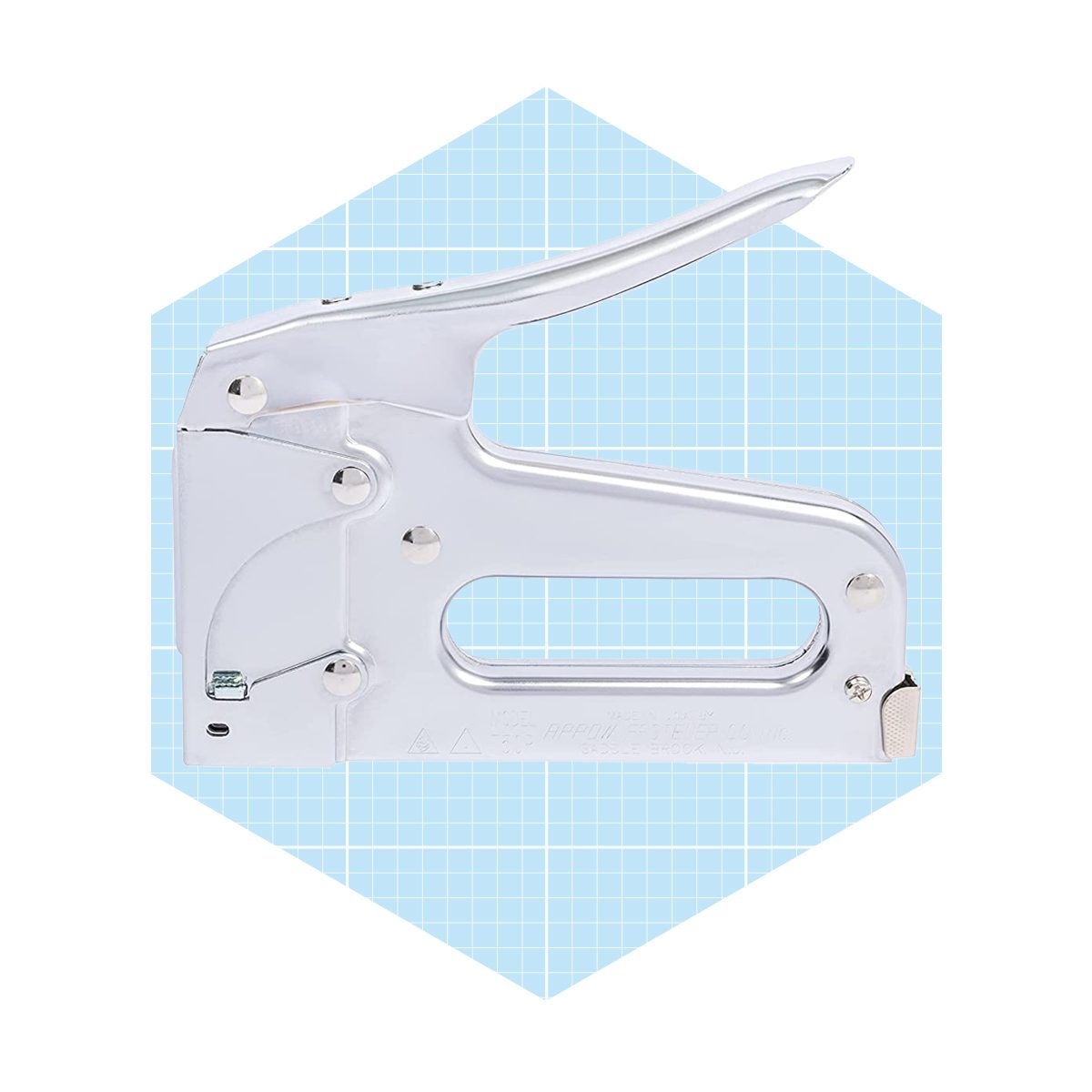

Manual staple gun

The staple gun features a spring-loaded trigger you squeeze to eject a staple. It’s intended for light- and medium-gauge staples with narrow and medium-width crowns.

Use for: Upholstery, sheet plastic, house siding paper, woodcrafts, flooring underlayment and carpeting.

Pros

- Lightweight and portable;

- Easy to load;

- Accepts a variety of staples.

Cons

- Squeezing the trigger repeatedly can be tiring;

- Staples tend to stick between the hammer and the front shield.

Electric staple gun

An electric staple gun can be corded or cordless. An internal electronic control eliminates the need to squeeze a trigger. It may accept longer staples than a manual one, depending on the model.

Use for: The same jobs requiring a manual staple gun, especially those calling for a large number of staples.

Pros

- Less tiring to use than a manual staple gun;

- More powerful.

Cons

- Can’t be used without battery or electric power;

- May accept only proprietary staples.

Pneumatic stapler

A pneumatic stapler is a heavy-duty tool similar to a nail gun. It runs on compressed air and can drive the longest, heaviest-gauge staples. Some electric staplers pack almost the same power as pneumatic ones.

Use for: Heavy construction, furniture framework, roof shingles, packaging and wire fencing.

Pros

- The most powerful stapler available;

- Can substitute for a nail gun in certain situations.

Cons

- Heavy;

- Needs an external compressor.

Flooring stapler

A flooring stapler is pneumatic with an angled drive head. It drives staples into the tongues of hardwood flooring.

Use for: Installing engineered or solid hardwood flooring.

Pros

- Makes hardwood installation faster and easier;

- Automatically sinks staples to the exact depth you need.

Cons

- Needs a compressor;

- Not useful for jobs other than flooring installation.

Hammer tacker

A hammer tacker is a type of manual staple gun. You swing it like a hammer. Each time the head strikes a hard surface, it ejects a staple.

Use for: Installing roofing or siding paper, floor underlayment or carpeting.

Pros

- Fast and easy;

- Longer reach than other staplers.

Cons

- Staples frequently stick;

- You need clearance to swing it.

Did you miss our previous article...

https://rsssuperfeeds.com/life-hacks/10-kitchen-color-trends-that-are-hot-right-now