Woodworking encompasses many different tasks. What may be an essential tool for one woodworker may go dusty and unused in another’s shop. To a newbie, all these tool choices can be overwhelming.

But no matter what type of woodworking you’re interested in, there are some basic skills universal to all. Every woodworker needs to cut, drill, shape, fasten, measure and finish, and requires the right tools to accomplish each task.

We’ve rounded up some of the most common tools in each category, highlighting what they’re used for, and which tools are most essential. If you’re working on a budget, don’t buy tools, then go looking for ways to use them. Start by choosing projects you enjoy, then only buy tools germane to those projects.

A few notes before we begin:

- We’re focused here on woodworking, not carpentry. There’s a great deal of overlap between the two, but in general, a carpenter creates buildings and structures while a woodworker creates objects ranging from chairs to fountain pens. Many tools listed here are also used in carpentry.

- We haven’t included safety tools. No matter what kind of woodworking you’re doing, always have the appropriate safety gear at all times.

- Names for tools and materials vary by region. You may see a coping saw called a hand saw or dovetail saw, but it’s the same tool.

Woodworking Tools That Cut

Cutting wood is perhaps the most foundational step in woodworking. Whether you’re building furniture or wall art, every woodworker must cut wood along the grain (rip) and across the grain (crosscut).

While modern power tools make cuts with incredible speed and precision, almost all woodworking cuts can be made by hand. Even today, finely detailed cuts are best made with a quality hand saw.

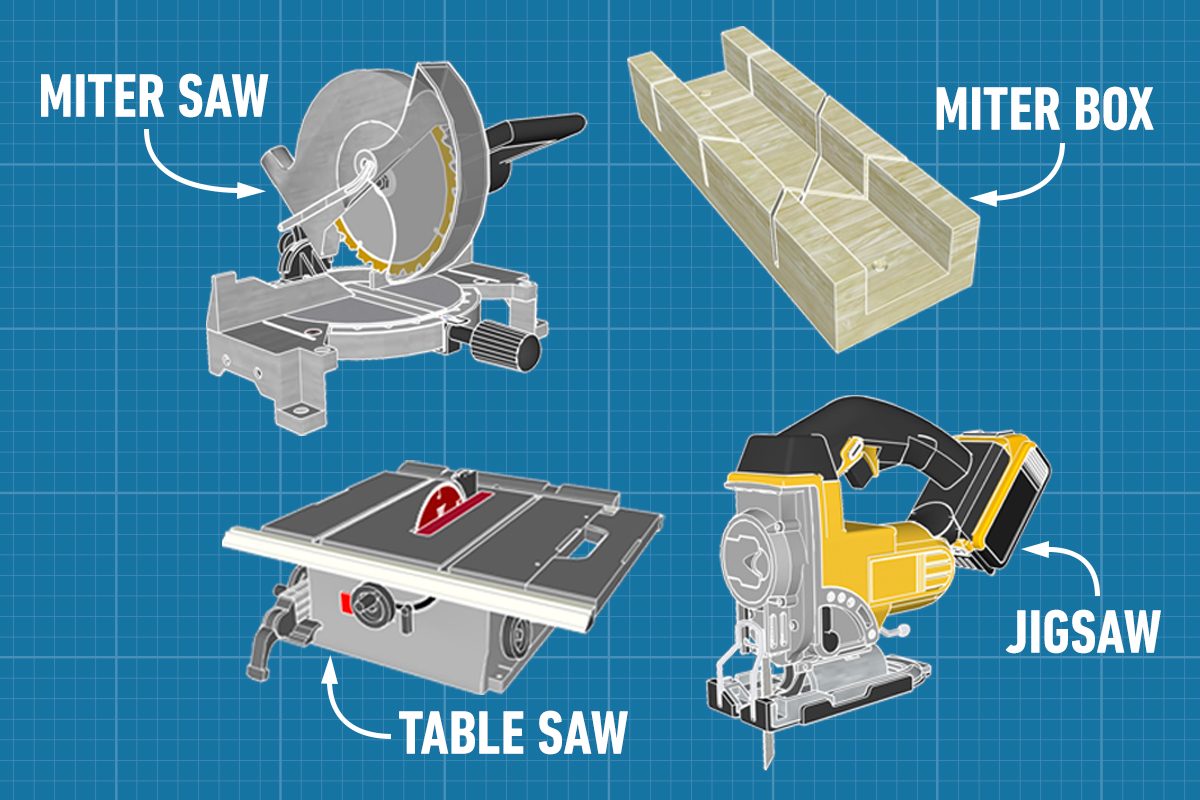

Table saw

A table saw can be used to rip and crosscut, making it a versatile tool at the heart of many workshops. Because of its wide, flat tabletop, it’s also ideal for cutting large pieces of flat stock like plywood. If you want to test it out before investing in a full-size table saw, consider a portable jobsite version, which often has a much more DIY-friendly price tag.

Miter saw

A miter saw is a more focused tool that makes fast, accurate and easily duplicated crosscuts. If you often work with relatively narrow stock (six inches or fewer), a miter saw is a massive time saver.

Miter box

If you don’t do enough crosscuts to justify purchasing a miter saw, consider a miter box. Essentially it’s a manually powered miter saw, with a plastic or wooden frame and slots to guide a hand saw at predetermined angles. Miter boxes allow relatively quick cuts at a rock-bottom price.

Jigsaw

A jigsaw is perfect for cutting curves and circles in a wooden surface. Beginners sometimes shy away when they encounter “chatter” (rapid vibration). But with a little experience and patience, a jigsaw is a valuable asset in any woodworker’s tool collection.

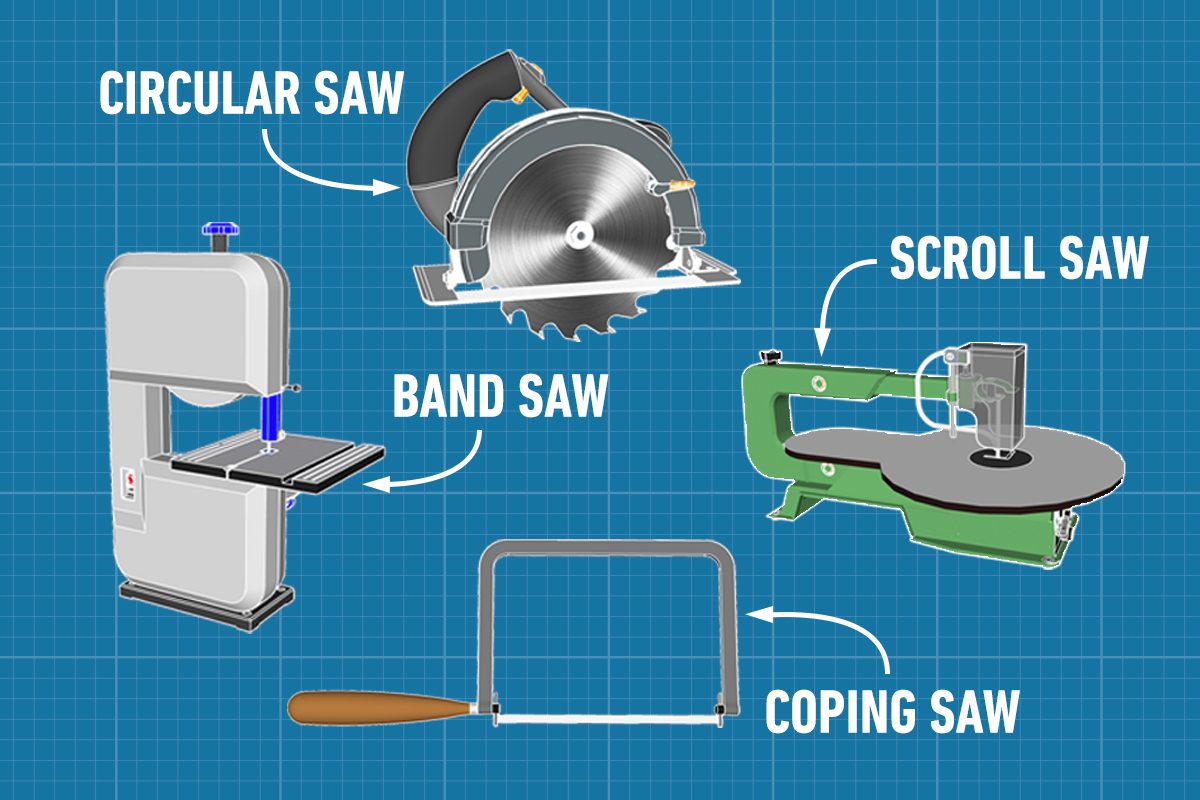

Coping saw

A narrow-bladed coping saw is perfect for highly detailed work like coping joints (hence the name), as well as cutting intricate curves and dovetail joinery.

Band saw

A band saw‘s vertical blade splits stock in half and cuts curves. Because it’s large, the band saw stays still while the woodworker repositions the cutting material. If you’re trimming a 2×6 into two 1x6s, a band saw is far superior to running it through a table saw twice.

Scroll saw

A scroll saw is a smaller version of a band saw. With its more limited mouth opening, a scroll saw is intended for detailed work on smaller stock. If you’re doing fiddly details in thin wood, it works magnificently.

Circular saw

A circular saw is primarily a carpenter’s saw, but it also has its place in a woodworker’s tool collection. If you only make the occasional cuts in plywood, it’s often better use to break out a circular saw than invest the space and money in a full table saw.

Woodworking Tools That Drill

Drilling is an essential part of woodworking, whether it’s pilot holes for nails and screws or dowels to hold your work in place. Your tool choices include:

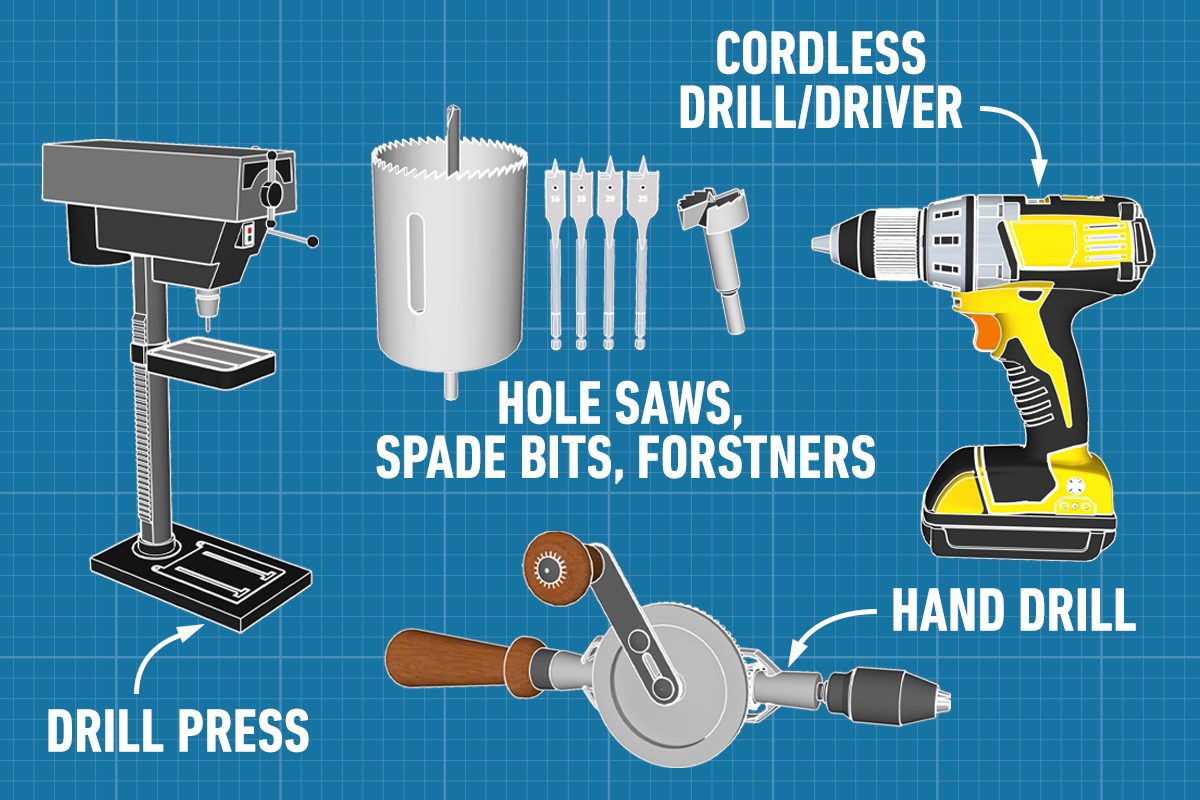

Cordless drill/driver

A few decades ago, a cordless drill was something of a luxury for a woodworker. Today, the many low-cost options on the market make it a must-have. Most woodworkers own a single drill/driver for boring holes and setting screws.

Drill press

Some holes need a level of precision that simply can’t be duplicated freehand with a cordless drill. In those instances, a drill press can make accurate and easily replicated holes.

Hand drill

A hand (manual) drill has become something of a specialty tool. However, its precision and ability to drill in minute increments can be extremely helpful for working with thin or valuable material.

Hole saws, spade bits, Forstners and other specialty bits

When boring holes, the drill is only part of the equation. Many woodworkers amass a collection of hole saws, spade bits, step bits, Forstners and other specialty bits.

Rather than spending money on a wide assortment all at once, it’s usually best to pick these up as needed. Trust us, before long you’ll find yourself with a surprising assortment.

Woodworking Tools That Shape

All kinds of tools can shape wood. Shaping can happen early or late in the project. In the case of woodcarving and wood turning, it essentially is the project.

These woodworking tools shape:

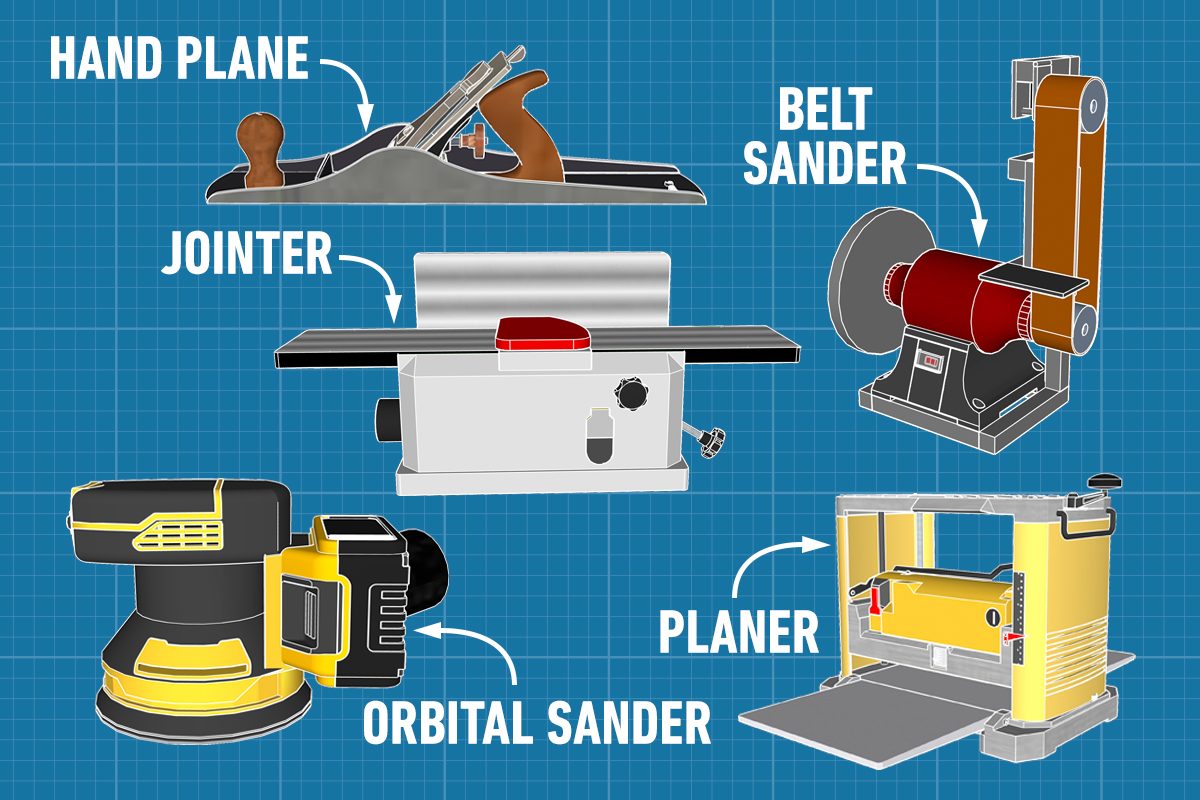

Hand plane

This simple tool has been around for centuries, and it’s still one of the most effective. A well-cared-for plane that’s been carefully calibrated removes material quickly or in transparently thin layers. These come in lots of sizes and styles. For most beginner woodworkers, the Stanley six-inch block plane is a great start.

Orbital sander

An orbital sander makes life much easier when you’re ready to smooth out a wooden surface or hide unwanted blade marks.

Belt sander

A belt sander can remove material extremely quickly. It’s such an aggressive tool you have to be careful not to overdo it.

Planer

A planer reduces the thickness of boards and makes them uniform. It’s a great tool if you’re buying rough lumber to save money. A planer ensures two opposite faces are even and parallel.

Jointer

A jointer is often used in conjunction with a planer. Jointers shape the length and edge of lumber, creating a clean right angle. If you’re laying pieces of lumber side-by-side — say, for a table top — a jointer will ensure the pieces fit snugly together.

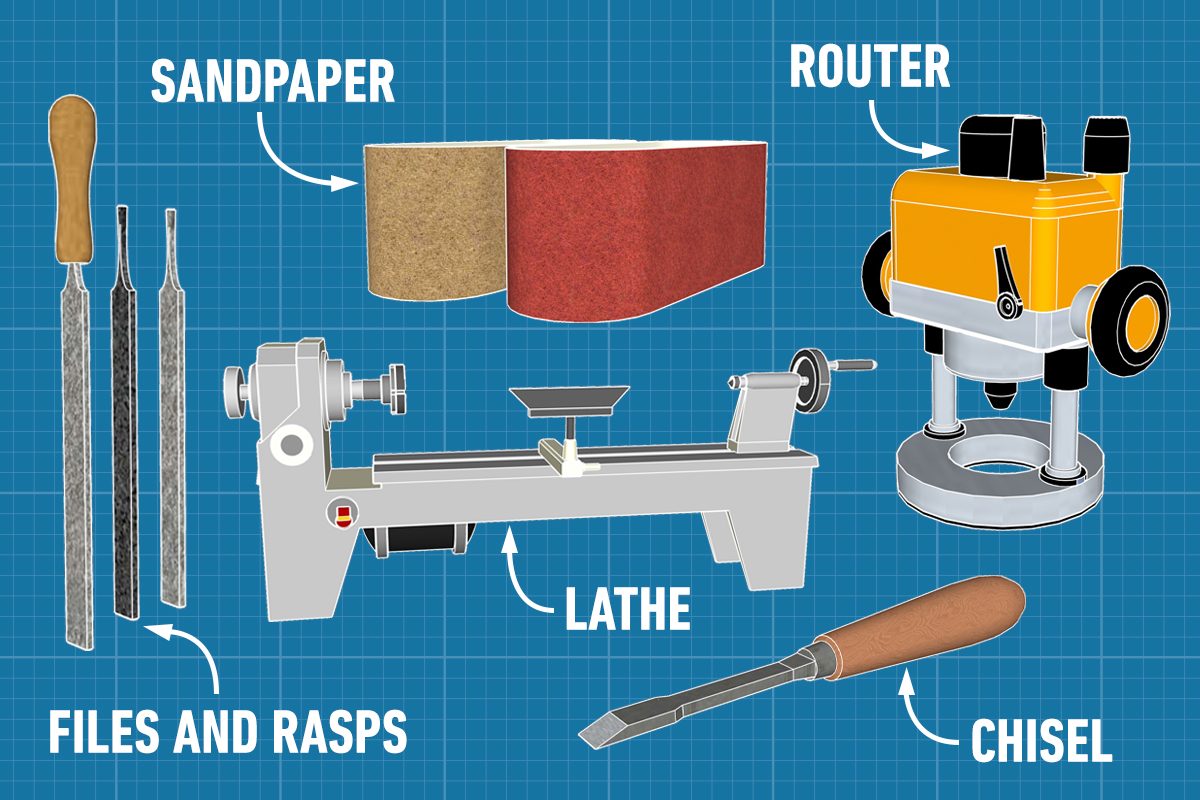

Sandpaper

Because it gets used up and replaced, sandpaper can be considered a “material” instead of a tool. But it’s essential in the wood shop, so we included it here.

Sandpaper is especially good for detailed work or curved surfaces. Once the grit is gone, don’t hesitate to discard it. Don’t forget the old DIY saying, “Life is short, abrasives are cheap.”

Lathe

If you’re interested in wood turning, a lathe will be at the heart of your shop. There’s something magical about seeing a wood turner at work, with the wood chips flying and the completed item slowly emerging from the spinning material.

Chisel

A chisel shapes everything from hinge mortises to sculptures. While the size and shape depends on your specific needs, some sort of quality, well-sharpened chisel is essential for almost every type of woodworking.

Router

A router is great for changing the edge profile of your project. Whether you go with a palm router on shelving or a table router to make custom wood trim, there are a wide range of uses for this handy tool.

Files and Rasps

Hand files and rasps remove and shape wood. Files make smaller changes and smooth surfaces, while rasps remove layers of wood. Combo file and rasp tools allow the user to easily move between the two tasks.

Woodworking Tools That Fasten

Once you’ve got your wood in shape, you need to fasten it together. Woodworkers use these tools for fastening:

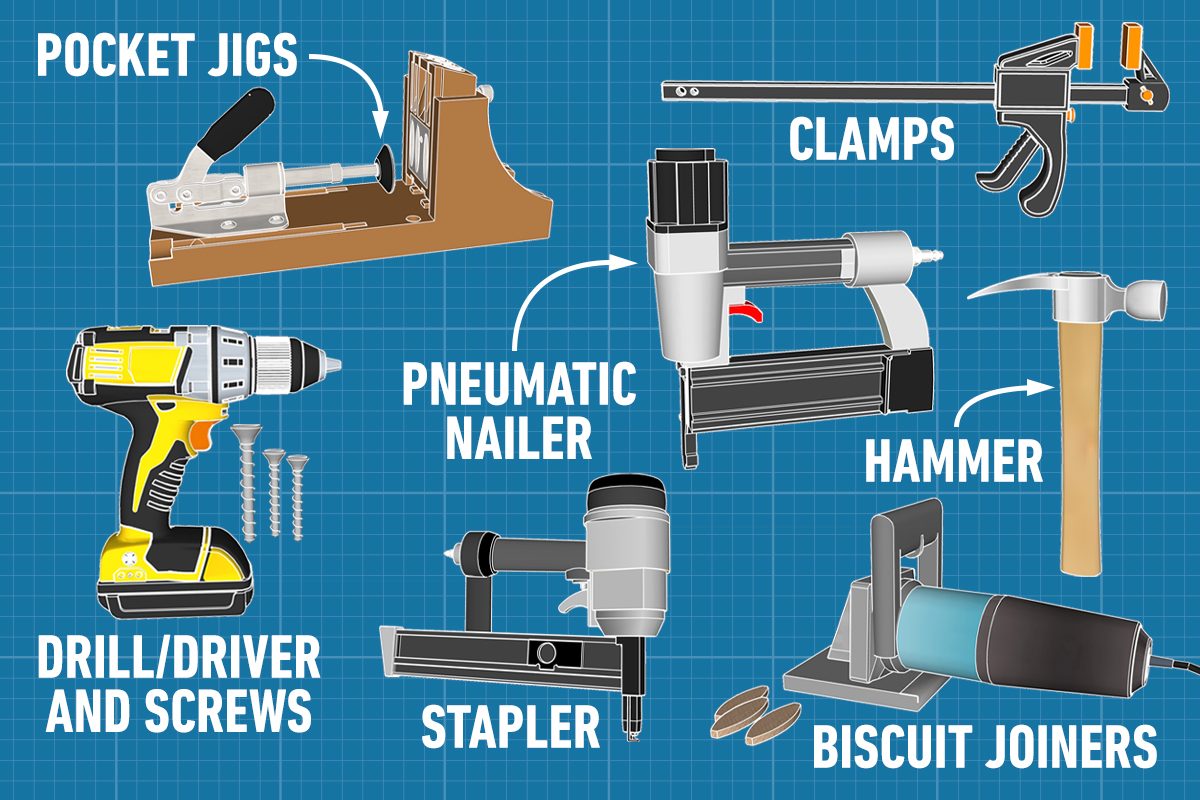

Hammer

A selection of hammers and mallets, along with nails and other fasteners, allow you to secure almost anything.

Pneumatic nailer

Pneumatic nailers are phenomenal tools if you expect to sink a lot of nails, or want a good multipurpose shop tool.

Drill/driver and screws

Screws are another great way to fasten wood together. You’ll use your drill/driver to sink screws and drill pilot holes to minimize splitting.

Stapler

Sometimes a staple is all that’s needed to hold workpieces together. Both manual and pneumatic staplers are especially helpful if you’re attaching upholstery to your project.

Pocket jigs

The most popular pocket hole jigs are by Kreg. Pocket holes are often used in furniture construction to hide fastener heads.

Biscuit joiners

Biscuit joiners essentially cut a narrow slot into two pieces of abutting wood, allowing a thin wooden oval (the biscuit) to be glued or set in place. In that way, they’re like a horizontal dowel.

Clamps

Whether holding pieces tight to allow glue to dry or stabilizing before drilling holes, most woodworkers feel they can never have enough clamps.

Woodworking Tools That Measure

“Measure twice, cut once” is sage advice for anyone working with wood. But measuring includes checking for square, checking for level and finding ways to make repetition easy.

Measuring is so important there are far more specialty tools than we list here, from calipers to try squares to moisture meters. Here are some of the most common woodworking measuring tools.

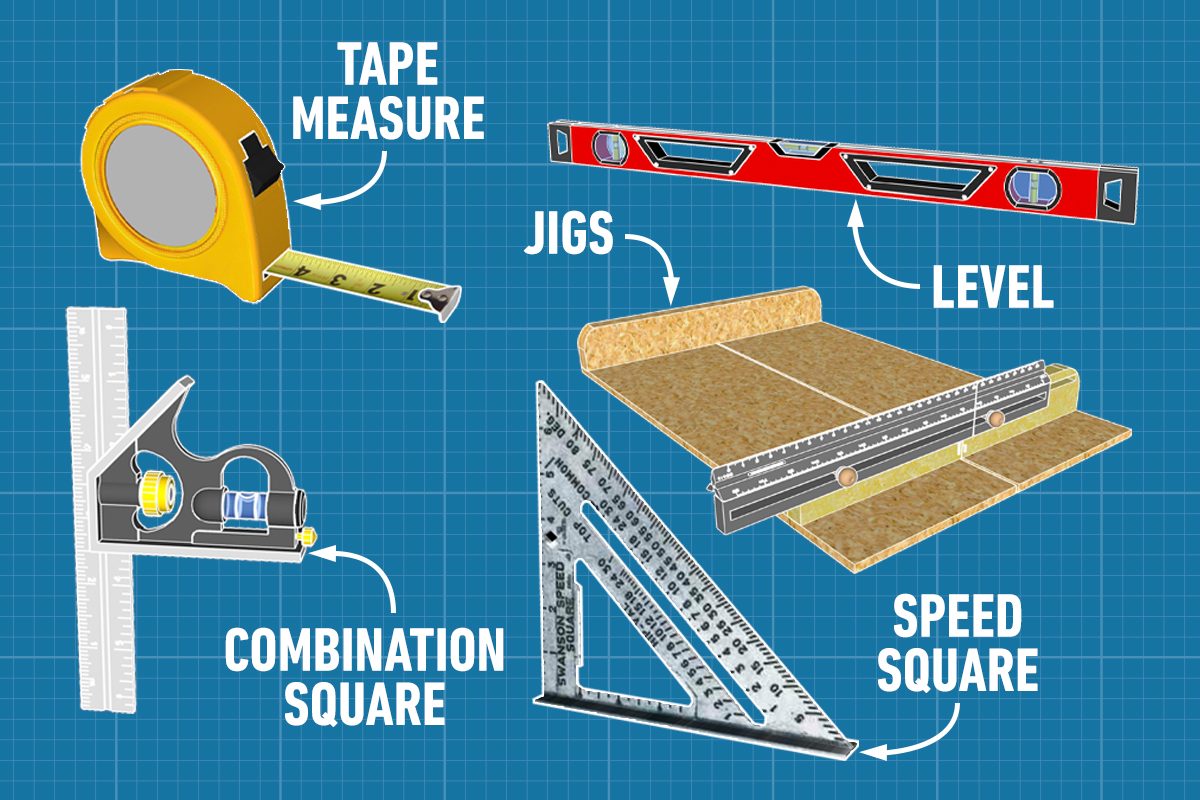

Tape measure

Found in almost every woodworker’s toolkit, a good tape measure is one of the most frequently used tools on this list.

Level

Levels are great for checking level and plumb. Longer metal levels often do double duty as a straightedge.

Combination square

A combination square is useful for planning cuts, but also vital for calibrating your machinery. Table and miter saws out of square or level will cause hours of frustration.

Speed square

Carpenters tend to favor a Speed square more than woodworkers, but these small and convenient tools are a good investment. If possible, opt for a metal square; plastic ones can warp in heat and are easily damaged in a rough and tumble work environment.

Jigs

A jig is a magnificent time saver, and can be used as a de facto measuring device. Jigs guide your tool to help you make identical cuts, curves or finishes, greatly reducing the measuring involved in each process.

Predesigned jigs are available, but most woodworkers find making their own allows for precise construction. If you’re making multiple identical cuts, even a single-project jig will often save more time than it takes to construct.

Woodworking Tools and Materials for Finishing

After you’ve done all the cutting, shaping and refining, don’t falter at the end! Use the same level of care to finish you project to ensure it’s something you’re proud of.

These woodworking tools are used for finishing:

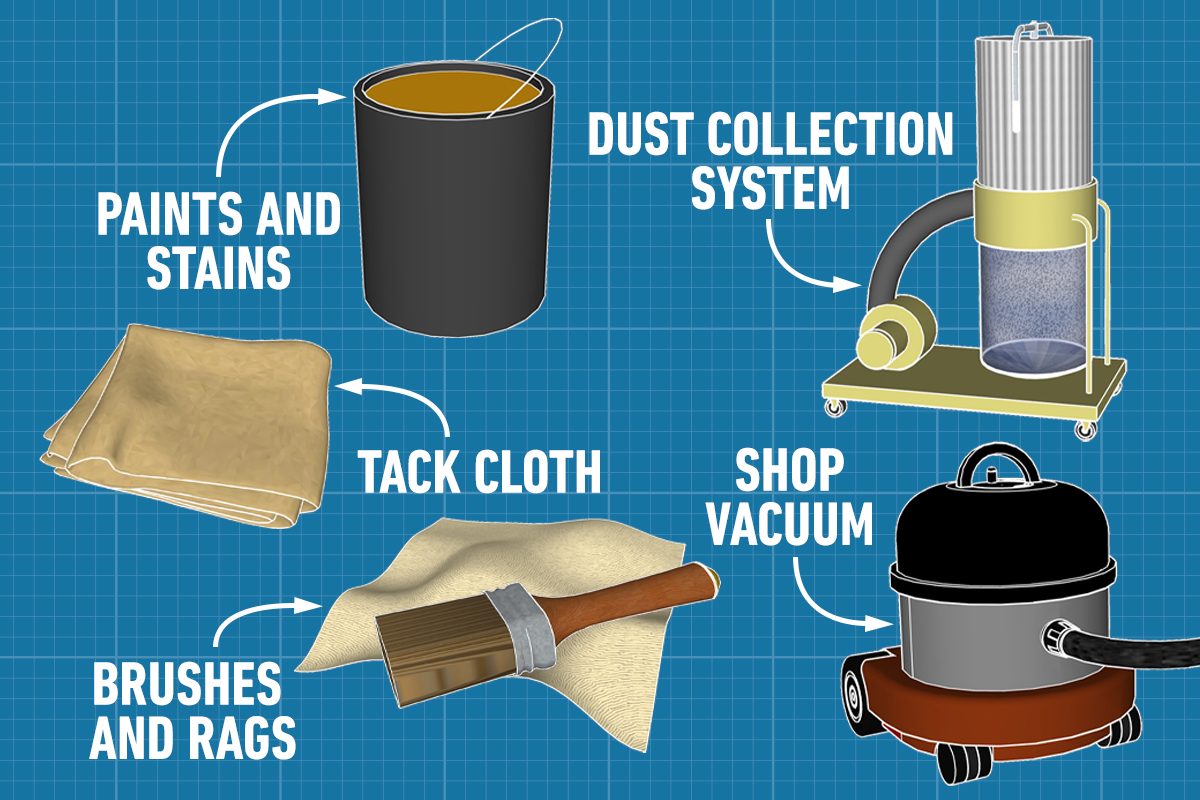

Paints and stains

Every project has its own needs and every woodworker their own preferences for finish coats. Experiment with different brands and materials to find the products that give you the best results.

Brushes and rags

A collection of brushes and rags will make paint and stain application much easier. This is another area where personal preference comes into play. Try out different materials and brush types to find your favorites.

Tack cloth

Tack cloth is coated fabric used to wipe down surfaces between finish coats. Some woodworkers swear by them and others skip them entirely.

Keep dust out of your finish

Dust collection system: Don’t try to finish your project while sawdust and debris hang in the air. That gorgeous wet stain won’t look so good in a couple of hours when it’s littered with fallen sawdust. A dust collection system sucks all that dust out of the air as you’re working. This makes it easier to finish your projects, and it’s healthier for your lungs.

Shop vacuum: A dedicated workshop vacuum can be the power behind a dust collection system, or supplement a dedicated system. Either way, it helps keep your shop clean and your workspace a little less chaotic. A good shop vacuum also hooks up to the exhaust ports on various saws to minimize dust expulsion.

Did you miss our previous article...

https://rsssuperfeeds.com/life-hacks/8-easy-woodturning-project-ideas